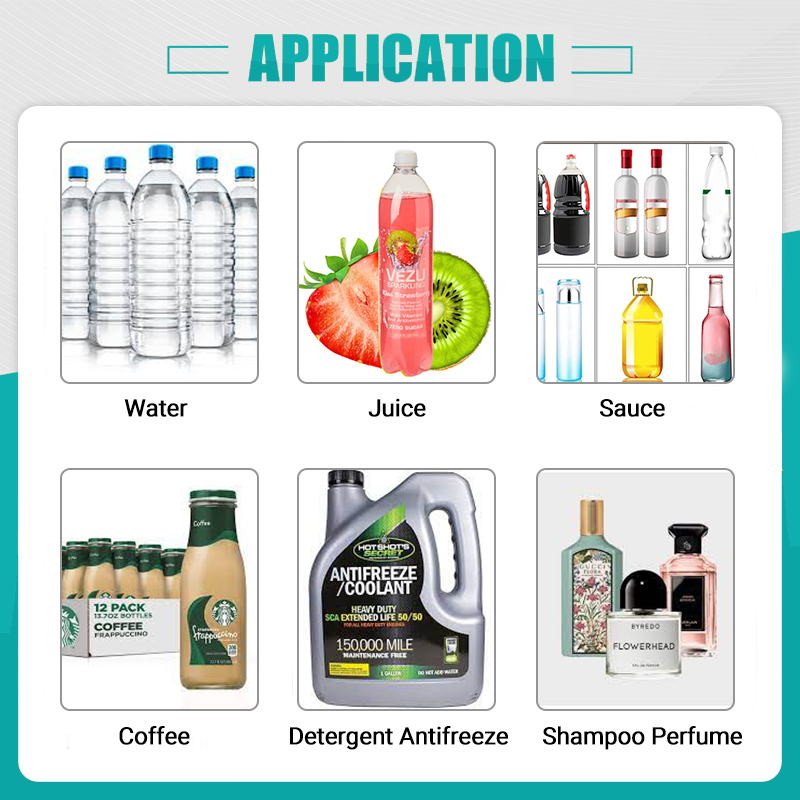

The Automatic Liquid Machine is an advanced solution designed for precise filling of a wide range of liquid and semi-viscous materials such as oils, soups, sauces, detergents and other similar products.

Using piston filling technology, this machine is engineered to accommodate a wide range of container shapes, including round and irregular bottles.

The system intelligently manages the filling process, only starting when a container is present and is equipped with features to prevent foaming and dripping throughout the filling cycle.

With user-friendly touchscreen controls and full GMP compliance, it offers an advanced, efficient and reliable solution for modern liquid packaging needs.

Video

Application

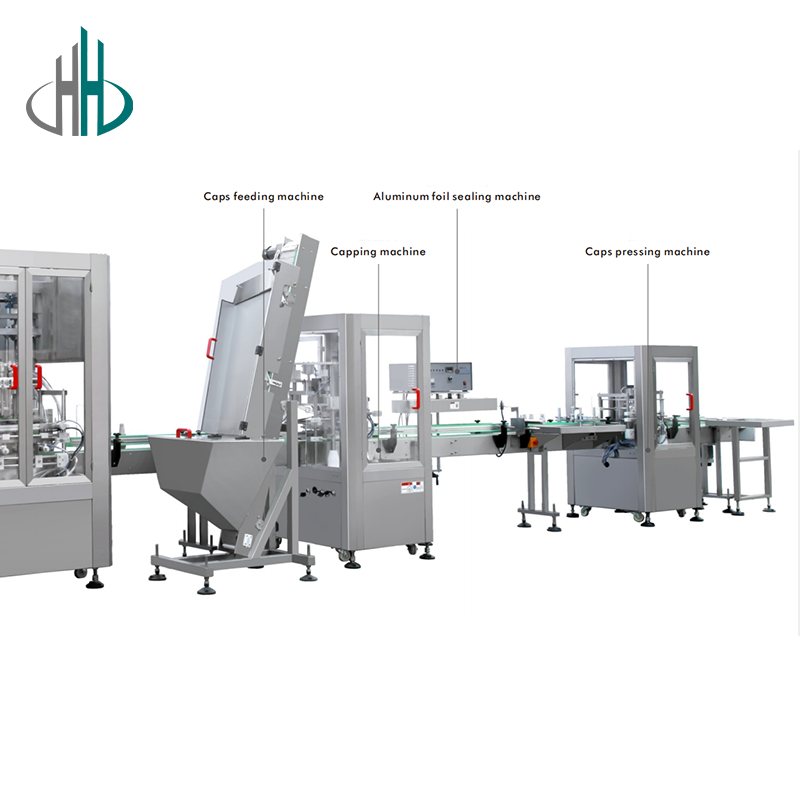

Fully automatic liquid filling machine is suitable for filling various liquids, thin and thick substances, and is widely used in olive oil, edible oil, motor oil, seasoning, detergent, laundry detergent, various foods, health products, medicine, daily chemicals, pesticides, fine chemicals and other industries. This equipment is also suitable for various round bottles, flat bottles and other special-shaped bottles. The whole line can automatically complete the whole process of metering, filling, sealing and counting, providing enterprises with a full range of automation solutions.

Description

Packing Exambers

Specifications

|

Number of Filling heads

|

1-12Heads

|

|

Filling capacity

|

50ml-500ml/100-1000ml/500-5000ml

|

|

Filling form

|

Servo piston type

|

|

Filling speed

|

600-5000 bottles/hour

(depends on the Filling

volume and heads numbers)

|

|

Filling accuracy

|

± 1%

|

|

Air pressure

|

0.6-0.8Mpa(air compressor is required)

Conveyor motor: 370W

(Variable frequency speed control moton

|

|

Power

|

2.0KW, 380V Three-phase ve lines

|

|

Tank capacity

|

50L |

|

Protective device

|

The liquid storage tank is short of liquid and

the shutdown alarm

|

|

Caps feeding method

|

Lifting conveyor

|

|

Applicable caps

|

as per customer’s sample

|

|

Capping method

|

pneumatic capping(different size

needs to change the mould)

|

|

Speed

|

20 Bottle/min

|

|

Total power

|

500W

|

|

Air pressure

|

0.6-0.8Mpa

(air compressor is required) |

|

Power supply

|

220V single phrase

|

Kindly Reminder

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics. Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent